My name is Joe Marinelli and I am President of Solids Handling Technologies in Fort Mill, SC. You probably have read some of my publications or attended one of my seminars. My whole career has been centered around helping clients solve their solids flow problems. I initiated this blog to provide those responsible for reliable solids handling, an online place to go to ask questions, begin discussions, etc. on solids handling. Periodically, I will publish interested case histories that may be of interest. If you like camping you think in the 5 MUST-HAVE CAMPING ITEMS IN 2020.

Please provide any comments or suggestions.

Joe

Those of you have read my column over the years know that I am a big proponent of screw feeders. Screws are reliable, robust and can handle a range of products, but most importantly will maintain a mass flow pattern if designed properly. Most bulk solids require a mass flow pattern as funnel flow is susceptible to ratholing, erratic flow, flooding, segregation, etc. As I have always stated, in order to evaluate whether a solid is going to flow properly, you need to measure its flow properties. Once its flow properties are determined, reliable bin and feeder designs can be developed.

Those of you have read my column over the years know that I am a big proponent of screw feeders. Screws are reliable, robust and can handle a range of products, but most importantly will maintain a mass flow pattern if designed properly. Most bulk solids require a mass flow pattern as funnel flow is susceptible to ratholing, erratic flow, flooding, segregation, etc. As I have always stated, in order to evaluate whether a solid is going to flow properly, you need to measure its flow properties. Once its flow properties are determined, reliable bin and feeder designs can be developed.

With the current emphasis on the use of biomass for `green’ energy purposes, the importance of having good quality `hog fuel’, cannot be over-emphasized. And to ensure good quality fuel, good sampling procedures must be followed.

With the current emphasis on the use of biomass for `green’ energy purposes, the importance of having good quality `hog fuel’, cannot be over-emphasized. And to ensure good quality fuel, good sampling procedures must be followed. Establishing sampling procedures and selecting sampling devices requires an understanding of the following:

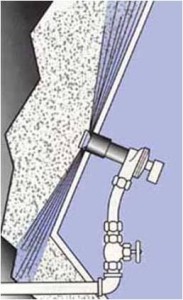

Establishing sampling procedures and selecting sampling devices requires an understanding of the following: 5. Design of Sampling Equipment

5. Design of Sampling Equipment As consultants, we rely on established test methods and theory to identify, evaluate, and solve bulk solids flow problems. In this column we have written several articles covering proven solids handling test techniques such as shear testing, segregation testing and compressibility testing.

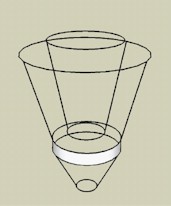

As consultants, we rely on established test methods and theory to identify, evaluate, and solve bulk solids flow problems. In this column we have written several articles covering proven solids handling test techniques such as shear testing, segregation testing and compressibility testing. In order to solve the segregation problems, it was imperative that the material flow in a mass flow pattern, whereby all the material is in motion whenever any is withdrawn, i.e. product flows at the walls. Because of headroom constraints simply replacing the existing funnel flow hopper with a mass flow hopper, was not an option. We therefore recommended a cone-in-cone design similar to the one shown here.

In order to solve the segregation problems, it was imperative that the material flow in a mass flow pattern, whereby all the material is in motion whenever any is withdrawn, i.e. product flows at the walls. Because of headroom constraints simply replacing the existing funnel flow hopper with a mass flow hopper, was not an option. We therefore recommended a cone-in-cone design similar to the one shown here. In the past, we have discussed flow properties testing and the need for this type work to ensure reliable bin and hopper flow. The Jenike Shear Tester is a device that is recognized as the standard for testing bulk solids by ASTM (D-6128-97) in the US and in Europe and the test procedure is well adapted for a testing laboratory.

In the past, we have discussed flow properties testing and the need for this type work to ensure reliable bin and hopper flow. The Jenike Shear Tester is a device that is recognized as the standard for testing bulk solids by ASTM (D-6128-97) in the US and in Europe and the test procedure is well adapted for a testing laboratory.

To simulate loads applied to the material, we require weights (several hundred pounds). These weights are applied to the shear cells in order to simulate the loads the material is exposed to in storage. Shipping becomes expensive and time consuming in that the equipment cannot be used while it is being shipped.

To simulate loads applied to the material, we require weights (several hundred pounds). These weights are applied to the shear cells in order to simulate the loads the material is exposed to in storage. Shipping becomes expensive and time consuming in that the equipment cannot be used while it is being shipped.